The construction of one of the world’s highest wind turbine towers, created by the Spanish business Nabrawind Technologies, has begun in Eslava, northern Spain. The goal of this project is to test a revolutionary design and assembly method by building a full-scale prototype in place of the industry’s present massive, expensive cranes. After installation, the prototype will undergo a fatigue test that, in only six months, will replicate 25 years of real-world usage.

Nabrawind Technologies Has Started Installing One of the World’s

“With this test, the performance of the tower during operation will be confirmed more quickly. Ion Arocena, the head of the NBTECH Tower Program, stated that this will increase the structure’s dependability and reduce any technical hazards before to the first pre-series.

This will be accomplished by utilizing a unique method that creates loads on the tower’s upper portion by carefully oscillating it in order to quickly imitate real-world situations.

This test procedure was developed for the NEVA project but has never been used on a wind turbine tower. The National Renewable Energy Center of Spain is a partner in the project, which is funded by FEDER money provided by the Spanish Ministry of Economy, Industry, and Competitiveness.

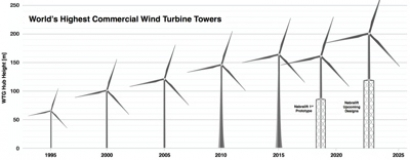

The new construction will allow the tower to eventually reach heights of up to 200 meters thanks to its self-erecting technology, which eliminates the need for big cranes.

However, NBTECH has fixed the height of their prototype at 160m to be consistent with the state of the market. Even so, it will continue to be the highest wind turbine tower outside of Germany.

As a result, the hub height of the NBTECH prototype tower will be 160m overall. It consists of a frame structure with three columns that is 86 meters high and was created and patented by NBTECH, and a traditional tower that is 71 meters high that is affixed on top.

The Nabralift, a structure created by NBTECH, stands out for its proprietary assembly mechanism, a novel self-erecting technique utilizing hydraulic jacks on the ground. This makes it possible to raise the tower by adding new modules from below. Because the tower is made up of smaller components, specialist trucks and cranes are not required. This new approach represents significant improvements in the shipping and tower assembly logistics.

Under the brand name Nabrajoint, the business has also created technical solutions for wind turbine blades.

According to Javier Callén, head of the NBTECH Modular Blade Program, “basically it consists of a unique connection for a modular blade that will allow the shipment of huge wind turbine blades in two or more portions.”

Due to its construction being 20% lighter than a conventional tower of the same height, its ease of transport and logistics, its lack of need for specialized lorries or cranes, and its installation on a foundation of three concrete pads, the Nabralift technology solution offers a significant cost saving compared to conventional towers of up to 15-20% (depending on the height and power output of the wind turbine).

Each component of the tower was created by NBTECH utilizing traditional manufacturing techniques, making it simple to deploy on any continent while maintaining a high level of dependability.

With the goal of delivering the first pre-series in 2019, NBTECH has recently finalized a number of agreements to manufacture its tower and blade components for supply inside Europe. Due to the significant level of interest displayed by potential clients, deployment across APAC and LATAM is anticipated to happen shortly.